See the Teaser Video

See the Teaser Video

See the Full Film on YouTube

See the Full Film on YouTube

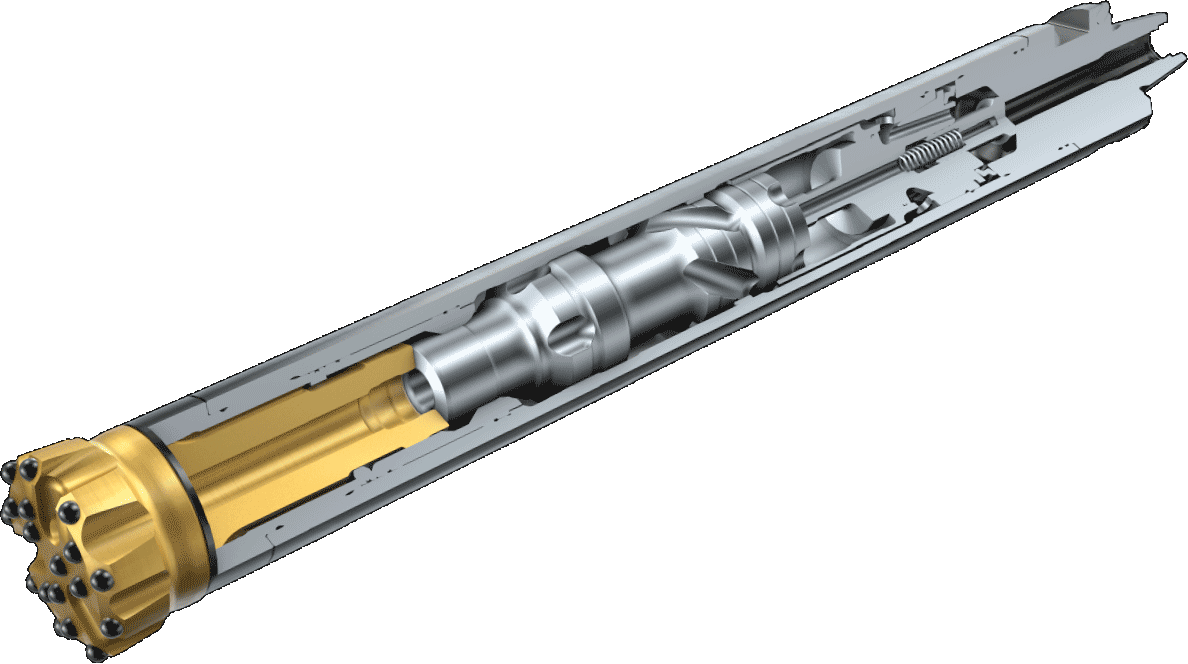

The most premium Sandvik hammer arrives to the market to meet the continued demand for increased productivity through cutting edge solutions.

See the Teaser Video

See the Teaser Video

See the Full Film on YouTube

See the Full Film on YouTube

See the Teaser Video

See the Teaser Video

See the Full Film on YouTube

See the Full Film on YouTube

The mining industry continues to demand even higher levels of productivity. Performance takes precedence thanks reduced handling and less downtime of the RH560 hammer.

With its enhanced air cycle and piston design, the RH560 delivers higher striking power leading to more power output. With less inside parts this hammer provides outstanding reliability. We have simply combined the reliability of our RH460 yet keeping the simplicity of RH510. RH560 is here to stay.

With an ability to build up pressure gradually, the RH560 hammer starts up smoothly allowing for better and quicker collaring in any rock condition. Even in complex rock formations and against uneven surfaces. Exact collaring and straight holes are prerequisites for productive drilling with maximum advance, and lower overall costs. This saves overall drilling time and reduced frustration for the driller.

In almost any ground conditions RH560 will give you higher productivity, improved reliability and better drilling economy through less air consumption. Delivers the high impact and energy transfer needed to keep you going on and on.

With a focus on optimized air cycle, the hammer improves reliability and economy through cutting air consumption, increasing power and improving lubrication. This allows for drilling bigger sized holes at the same speed as a smaller hole with a standard hammer, giving high productivity in variable ground conditions. Not a patented piston.

The RH560 delivers high performance and added value to most drilling applications, thanks to the mechanical efficiency between the piston and drill bit that optimizes impact energy transmission to boost penetration rates.

More evenly distributed stress on the retainer shoulder leads to less wear on the bit.

Avoids the problem of availability and special orders. With a well proven standard shank you will not run into reliability issues.

No problem related to foot valve i.e breakage.

Reliability. With porting being done externally, the piston is free from cross drilled holes and therefore reduces stress induced failures.

The oil grooves ensure constant and consistent lubrication between the piston and internal parts which reduces galling related failures. When the air and oil mix passes the oil grooves they create turbulence, which acts as a dynamic seal. This ensures minimal air leakage.

The V-lock system is designed to prevent movement of internal components. By preventing movement of its components galling related failures are reduced.